Stainless Steel L Profile

200 INR/Piece

Product Details:

- Weight Varies with dimension and length, e.g., 1.58 kg/m for 25x25x3 mm

- Capacity Depends on section size and grade

- Surface Finish Brushed, Mirror, or Matte finish

- Dimension (L*W*H) Customized, common sizes: 20 x 20 mm up to 100 x 100 mm

- Usage & Applications Construction, Architectural, Fabrication, Interior Design, Machinery

- Product Type Other

- Trailer Use No

- Click to View more

X

Stainless Steel L Profile Price And Quantity

- 200 INR/Piece

- 1 Piece

- Cold Rolled / Hot Rolled

- Annealed or Hardened

- Excellent

- 304, 316, 202

- High

- Wooden Crate, Bundle with Wrapping

- 2 mm to 10 mm

- ±2 mm

- ASTM A276, AISI, DIN EN

- Sharp or Rounded

- Natural Silver

Stainless Steel L Profile Product Specifications

- L-shaped profile

- Stainless Steel (Grades 304, 316 available)

- Available as per requirement, typically 3 m to 6 m

- Construction, Architectural, Fabrication, Interior Design, Machinery

- No

- No

- Other

- Brushed, Mirror, or Matte finish

- Customized, common sizes: 20 x 20 mm up to 100 x 100 mm

- Varies with dimension and length, e.g., 1.58 kg/m for 25x25x3 mm

- Depends on size and application

- Depends on section size and grade

- Cold Rolled / Hot Rolled

- Annealed or Hardened

- Excellent

- 304, 316, 202

- High

- Wooden Crate, Bundle with Wrapping

- 2 mm to 10 mm

- ±2 mm

- ASTM A276, AISI, DIN EN

- Sharp or Rounded

- Natural Silver

Stainless Steel L Profile Trade Information

- 1 Piece Per Month

- 1 Days

Product Description

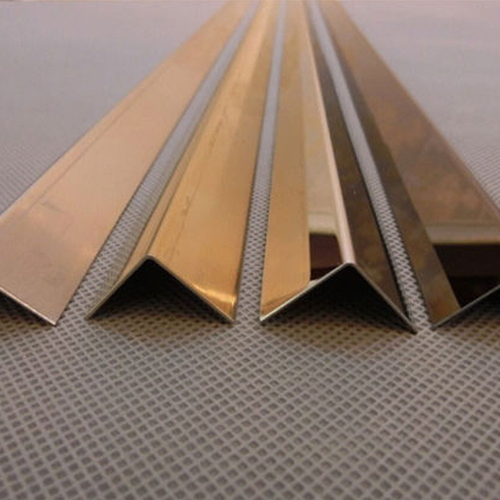

Stainless steel L profile, also known as stainless steel angle or angle iron, is a versatile and durable structural component commonly used in various construction and industrial applications. It is typically made from stainless steel, which offers excellent corrosion resistance and strength, making it suitable for both indoor and outdoor use.The L-shaped profile of stainless steel L profile resembles the letter "L," with two perpendicular legs that meet at a 90-degree angle. This design provides stability and support in a wide range of applications, including framing, support brackets, reinforcement, and edging. Stainless steel L profiles are available in various sizes, thicknesses, and finishes to suit specific project requirements.

Their resistance to rust and corrosion makes stainless steel L profiles ideal for use in environments where exposure to moisture, chemicals, or harsh weather conditions is a concern. They are widely used in the construction of buildings, infrastructure, machinery, and equipment, as well as in architectural and decorative applications.

In summary, stainless steel L profiles are a valuable structural element due to their durability, corrosion resistance, and versatility, making them an essential component in many industrial and construction projects.

Superior Corrosion Resistance

Made from top-quality grades like 304 and 316 stainless steel, these L profiles provide outstanding resistance against corrosion, even in harsh environments. This ensures the longevity and reliability of your structures, making them ideal for both indoor and outdoor use, such as in construction and architectural projects where durability is paramount.

Multiple Surface Finishes for Versatile Applications

Choose from brushed, mirror, or matte finishes to match your project's design requirements. The flexibility in surface treatment, coupled with sharp or rounded edges, ensures compatibility with various aesthetic and structural needs, whether for modern interiors or industrial machinery fabrication.

FAQ's of Stainless Steel L Profile:

Q: How is the stainless steel L profile manufactured?

A: Stainless steel L profiles are produced through cold rolling or hot rolling processes, conforming to international standards like ASTM A276, AISI, and DIN EN. Edges can be made sharp or rounded, and the profiles are then finished in matte, brushed, or mirror depending on application needs.Q: What grades of stainless steel are available for these L profiles?

A: The stainless steel L profiles are available in grades 304, 316, and 202. Grade 316 offers superior corrosion resistance, making it ideal for harsh or marine environments, while 304 and 202 are suited for general fabrication, construction, and architectural applications.Q: Where can stainless steel L profiles be used?

A: These profiles are widely used in construction, architectural projects, fabrication works, interior design, and machinery manufacturing due to their strength, corrosion resistance, and customizable dimensions.Q: What are the thickness and dimension ranges available?

A: Thicknesses range from 2 mm to 10 mm, with common cross-sections from 20 x 20 mm up to 100 x 100 mm. Lengths are typically between 3 m and 6 m, customizable according to project specifications.Q: How are these L profiles packaged and shipped?

A: To ensure safe transport, stainless steel L profiles are packed in wooden crates or securely bundled with protective wrapping. They are not typically transported using trolleys or trailers, especially for export shipping.Q: What is the main benefit of using these stainless steel L profiles?

A: The main advantage lies in their excellent corrosion resistance, high structural strength, and customization flexibility, which make them suitable for demanding structural or decorative uses across many industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email